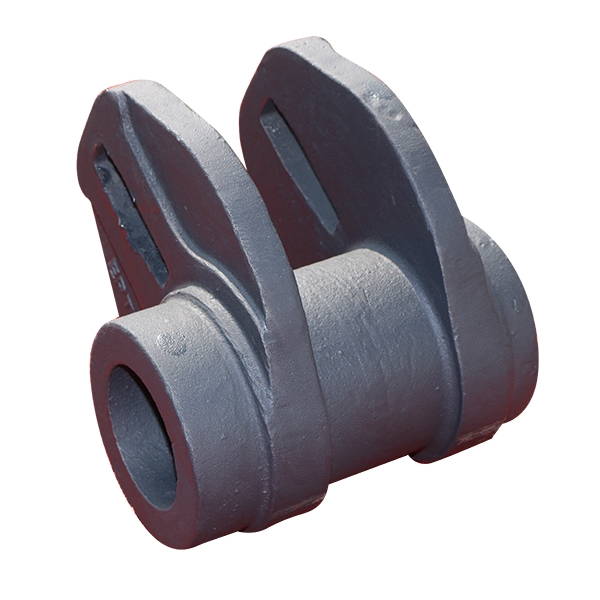

Products

JK30-2401001 Gearbox hood

Product Feature

Lost foam casting (also known as real mold casting) is made of foam plastic (EPS, STMMA or EPMMA) polymer material into a real mold with exactly the same structure and size as the parts to be produced and cast, and is dip-coated with refractory coating (strengthened) , smooth and breathable) and dried, it is buried in dry quartz sand and subjected to three-dimensional vibration modeling. The molten metal is poured into the molding sand box under negative pressure, so that the polymer material model is heated and vaporized, and then extracted. A new casting method that uses liquid metal to replace the one-time mold casting process formed after cooling and solidification to produce castings. Lost foam casting has the following characteristics: 1. Castings are of good quality and low cost; 2. Materials are not limited and suitable for all sizes; 3. High precision, smooth surface, less cleaning, and less machining; 4. Internal defects are greatly reduced and the structure of the casting is improved. Dense; 5. It can realize large-scale and mass production; 6. It is suitable for mass production casting of the same castings; 7. It is suitable for manual operation and automated assembly line production and operation control; 8. The production status of the production line meets the requirements of environmental protection technical parameters. ; 9. It can greatly improve the working environment and production conditions of the casting production line, reduce labor intensity, and reduce energy consumption.

Product Description

Lost foam casting (also known as real mold casting) is made of foam plastic (EPS, STMMA or EPMMA) polymer material into a real mold with exactly the same structure and size as the parts to be produced and cast, and is dip-coated with refractory coating (strengthened) , smooth and breathable) and dried, it is buried in dry quartz sand and subjected to three-dimensional vibration modeling. The molten metal is poured into the molding sand box under negative pressure, so that the polymer material model is heated and vaporized, and then extracted. A new casting method that uses liquid metal to replace the one-time mold casting process formed after cooling and solidification to produce castings.

Lost foam casting has the following characteristics: 1. Castings are of good quality and low cost; 2. Materials are not limited and suitable for all sizes; 3. High precision, smooth surface, less cleaning, and less machining; 4. Internal defects are greatly reduced and the structure of the casting is improved. Dense; 5. It can realize large-scale and mass production; 6. It is suitable for mass production casting of the same castings; 7. It is suitable for manual operation and automated assembly line production and operation control; 8. The production status of the production line meets the requirements of environmental protection technical parameters. ; 9. It can greatly improve the working environment and production conditions of the casting production line, reduce labor intensity, and reduce energy consumption.

Want to discuss what we can do for you?

Explore where our solutions can take you.