Products

Driving axle gearbox series

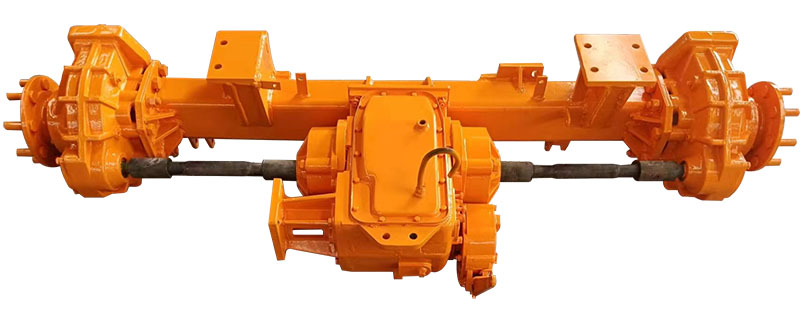

Y7 Hydraulic 4-speed Front Axle Assembly

Product Introduction:

Matching models: corn harvesters.

Technical parameters: I 29.29; II 7.19; III 14.608, Final driving gearbox ratio: 7.72 (85/11).

Weight: 712kg/unit. 260hp engine, fully loaded weight not exceeding 17 tons.

Installation wheel track can be customized.

Product Feature:

The case is rigid and compact, with four forward gears. The design eliminates the clutch and torque converter, which are high-priced components with high failure rates. The harvester uses a continuously variable transmission, cross-axis differential, and a reliable and durable clutch structure. It provides smooth transmission, low noise, strong bearing capacity, reliable connection, and easy installation. The continuously variable transmission structure, thickened output shaft, and helical gears are used. The strengthened shell increases the strength and reliability of the machine.

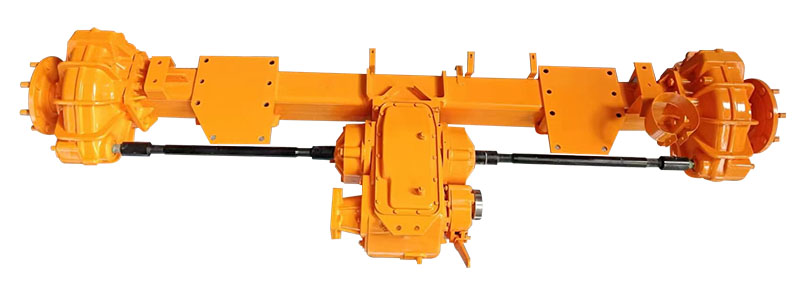

800 Hydraulic Axle Assembly

Product Introduction:

Matching models: 85-160 horsepower wheat, soybean, and corn harvesters.

Technical parameters: I 12.115; II 5.369, Final driving gearbox ratio: 6.09.

Weight: 475kg per unit.

Installation wheel track can be customized.

Product Feature:

(1) Strong rigidity of the gearbox body, compact structure, adopting straight-tooth gear engagement with sleeve shifting, smooth transmission, low transmission noise, reliable connection, and easy installation.

(2) Adopting hydraulic stepless speed regulation and plate friction clutch brake, easy to operate, greatly reducing driving labor intensity, high reliability, and low failure rate.

(3) The reliability of the stem and ear harvesting machine has been verified and it is deeply favored by a large number of users.

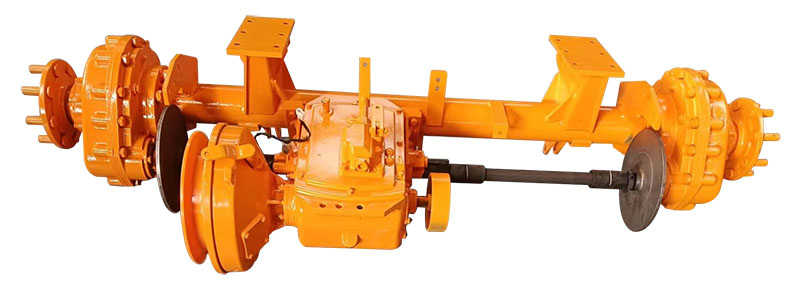

4YZP Self-propelled Corn Harvester Front Axle Assembly

Product Introduction:

Matching models: Corn harvester.

Technical parameters: I 22.644; II 9.403; III 3.747; R10.536; final driving gearbox ratio: 6.09.

Weight: 430kg/unit.

Installation wheel track can be customized according to user requirements, and static hydraulic type can be selected.

Product Feature:

(1) Sleeve gear shifting is adopted, which reduces the shifting impact and noise, and makes the shifting light and flexible.

(2) Large-capacity diaphragm spring clutch is adopted to make the clutch more durable, solve early failure of the clutch and early gear wear caused by it, and improve the reliability of the drive axle assembly.

(3) The strengthened single axle, half axle, and enclosed strengthened final driving gearbox increase the reliability of the drive axle assembly.

Want to discuss what we can do for you?

Explore where our solutions can take you.