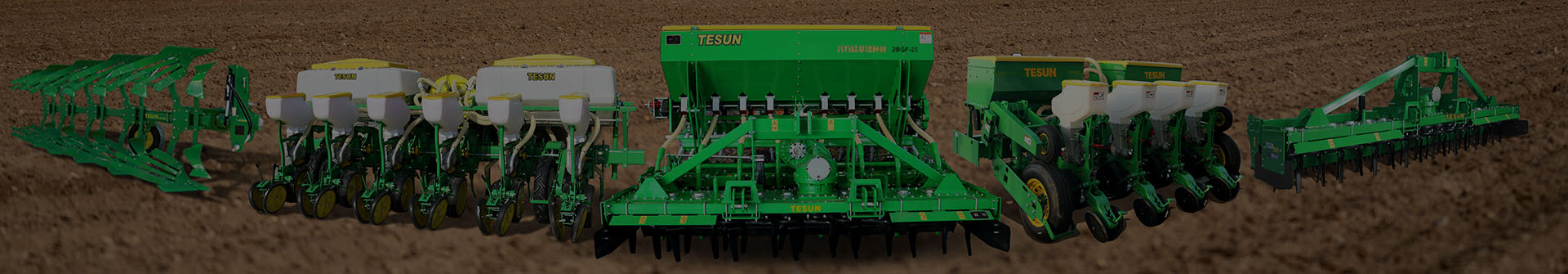

Products

1ZLD Series Combined Cultivator

Product introduction

The 1ZLD series combined cultivator is currently widely used as a pre-sowing land preparation machinery. It transforms the traditional single operation into a combined duplex operation. With one operation of the integrated land preparation machine, the purpose of crushing soil, leveling land, retaining moisture, soil-fertilizer mixing and precise cultivation can be achieved, fully meeting the agricultural technology requirements of seedbeds. The tillage depth is between 50-200mm, the optimal operating speed is 10-18km/h, and the land is fully ready for sowing after harrowing. Equipped with heavy-duty packer, the packer teeth are spirally distributed, which has a good compact effect. The seedbed after operation is solid on the top and loosening on the bottom, which can better retain water and moisture. The harrow frame is made of high-strength alloy, and the whole machine runs smoothly, is lightweight and reliable. It adopts hydraulic folding device, which has fast take-up and down speed and convenient transportation.

During the operation of this machine, the front disc harrow group loosens and crushes the soil, the subsequent soil crusher further breaks and compresses the soil, while causing the small clods and fine soil particles thrown up to fall on the surface, thus blocking the underground water evaporation. The rear leveling device makes the compacted seedbed even more level and forming an ideal seedbed with upper porosity and lower density.

Product Specification

| Model | 1ZLD-4.8 | 1ZLD-5.6 | 1ZLD-7.2 |

| Weight(kg) | 4400 | 4930 | 5900 |

| Notched Disc number | 19 | 23 | 31 |

| Round Disc number | 19 | 23 | 31 |

| Notched Disc diameter(mm) | 510 | ||

| Round Disc diameter(mm) | 460 | ||

| Disc space(mm) | 220 | ||

| Transportation Dimension(Length x Width x Height) | 5620*2600*3680 | 5620*2600*3680 | 5620*3500*3680 |

| Working Dimension(Length x Width x Height) | 7500*5745*1300 | 7500*6540*1300 | 7500*8140*1300 |

| Power(Hp) | 180-250 | 190-260 | 200-290 |

Product Feature

1.The combination of multiple working parts cooperates with each other to complete the loosening, crushing, leveling, and compaction in one operation, meeting the requirements for loosening and crushing with a porous and dense tillage layer structure that can retain water, preserve moisture, and provide high quality, efficiency, and energy saving features.

2.The tool is equipped with a hydraulic lifting triangle soil leveling device to effectively eliminate tractor tire indentations

3.The harrow depth adjustment mechanism can quickly adjust the working depth by increasing or decreasing the number of baffles.

4.The discs are arranged in a staggered pattern with a notched front and rounded back, which can effectively cut and crush the soil, and are equipped with maintenance-free bearings. The harrow legs are made of rubber buffer, which has obvious overload protection effect and effectively reduces the failure rate.

5.The packer is equipped with an independent scraper, which is easy to adjust and replace and is suitable for operations on clay soils.

6. High-quality steel is used for key components such as the main beam and frame, which are strengthened as necessary.

7.Custom-made U-bolts that have undergone special heat treatment are used in conjunction with high-strength bolts.

8.International quality hydraulic cylinders are more reliable.

Feature of 1ZLD Series

Hydraulic Lifting Triangle Soil Leveling Device

The Disc Depth Adjustment Mechanism

The discs are arranged in a staggered pattern with a notched front and rounded back.

The harrow legs are made of rubber buffer.

The packer is equipped with an independent scraper.

The Rear Leveling Device

Want to discuss what we can do for you?

Explore where our solutions can take you.